Saving OPEX with “AFT OPT” TECHNOLOGY and fulfill EEDI-3 and CII

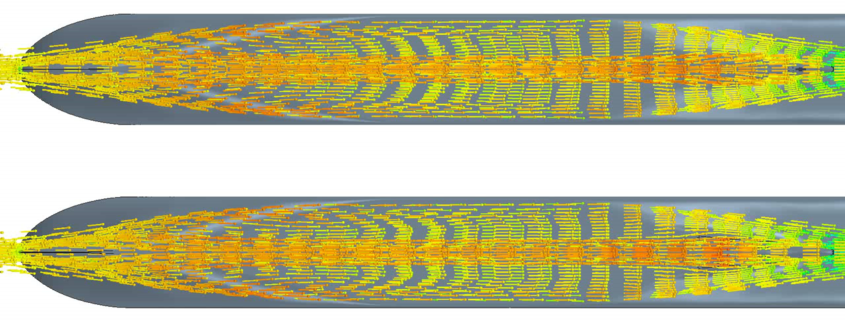

MOVENA offers qualified clients a unique ship newbuilding design service in joint cooperation with our technology partner “LR Shipdesign AG“. The “Patented Lindinger Hull” optimisation considers previously widely neglected hydro-dynamical and hydro-mechanical effects with an own software tool for CFD integration. The technology was developped originally based on aerodynamical analysis of aircraft wing systems (surface wing/compressed air). Physical effects were than uniquely applied to the interface between vessel and water.

SAVE FUEL COST AND ACHIEVE BETTER ENVIRONMENTAL PERFORMANCE AT THE SAME TIME!

Result: fuel savings between 5% and up to 10%+ compared with optimised traditional design methods – depending on ship type, speed, vessel geometry, propeller, rudder etc. Various business cases have proven the new approach.

In other words: very large container vessels save more than 1.5 mio USD/year fuel cost, Panamax bulkers save 300k USD/year easily.

We firmly believe that you MUST CHECK “room for improvement” for your newbuildings. LR Shipdesign is a PARTNER for design companies (“extended work bench”), not their competitor. You achieve and keep better CII ratings for your vessel even when your charterer does not operate the vessel in the best way possible (due to weather conditions, waiting time etc.).

The AFTship OPTimisation will be done based on an optimised design provided by owner, design office or shipyard. Best results can be achieved in case CFD, lines, …, hard points etc. will be made available to start optimisation from there. The optimisation results will be delivered in the respective data format (IGS).

The otimisation delivers proven results in particular for larger vessels (>130m) independent of ship type (passenger vessels, bulker, container vessels, tankers). In addition, substantial reduction of noise, vibration and savings such as for engine maintenance are provided on top. For arctic going vessels it is a “must check” option to be in compliance with oncoming regulations for noise reduction to protect the environment.

For discussion of this proven optimisation concept and for your application to enter the new world of energy efficiency, please contact Dr. Wasmansdorff: wff@movena-group.com

(photo: © R. Lindinger, Switzerland)